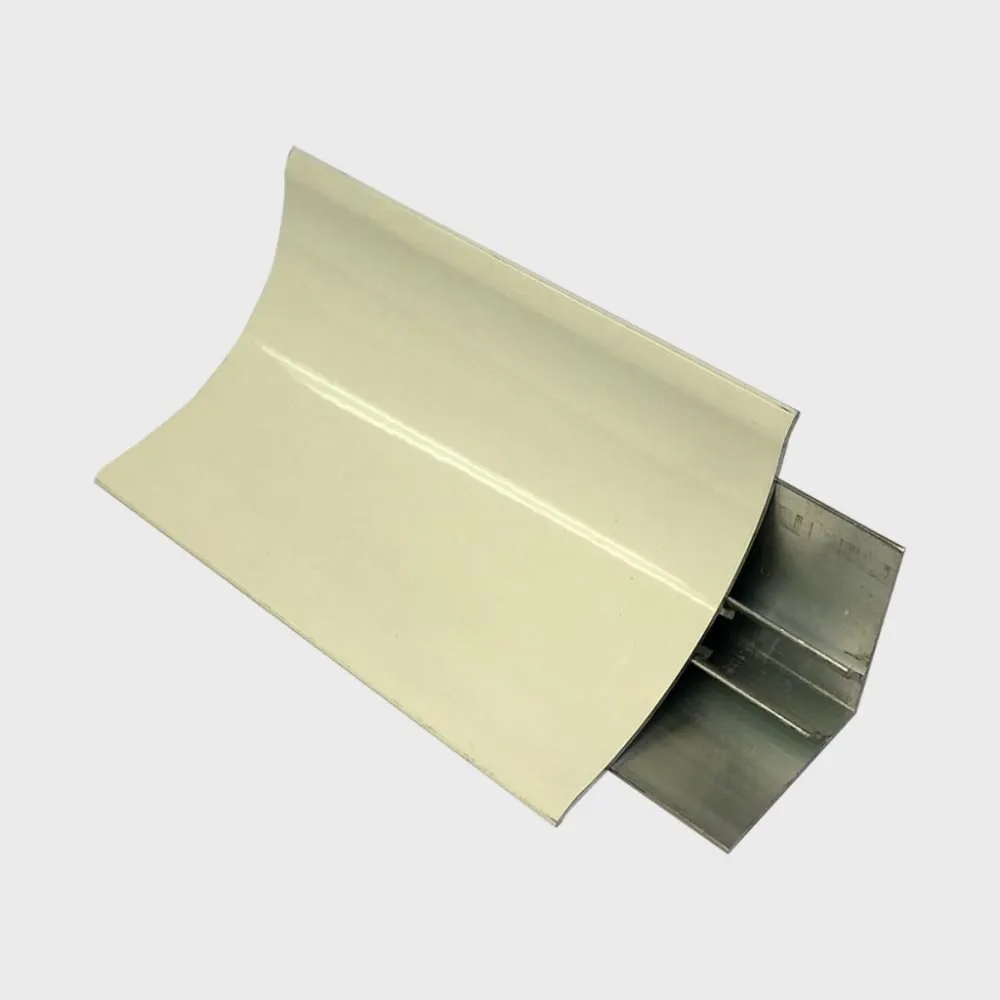

Aluminium Coving R 50 With Backing

Aluminum coving can be utilized in cleanroom panels to provide a clean and hygienic finish at the junction where the walls meet the ceiling. Cleanrooms are controlled environments used in industries such as pharmaceuticals, biotechnology, electronics, and healthcare, where it is essential to maintain stringent cleanliness standards to prevent contamination.

Here are some reasons why aluminum coving is commonly used in cleanroom panels:

- Clean and Hygienic Finish: Aluminum coving creates a smooth and seamless transition between the walls and ceiling in cleanrooms. Its non-porous surface is easy to clean and disinfect, minimizing the risk of contaminants accumulating in hard-to-reach areas.

- Resistance to Contamination: Aluminum is resistant to microbial growth, making it suitable for cleanroom environments where maintaining cleanliness and sterility is crucial. It does not provide a favorable environment for bacteria, fungi, or other microorganisms to thrive.

- Durable and Long-Lasting: Aluminum is a durable material that can withstand the rigors of cleanroom operations. It is resistant to corrosion, moisture, and chemicals, ensuring the longevity of the coving even in demanding environments.

- Easy Installation: Aluminum coving is typically lightweight and available in pre-formed sections, making it easy to install in cleanroom panels. The coving can be securely attached using adhesives or mechanical fasteners to ensure a tight and seamless fit.

- Compatibility with Cleanroom Standards: Aluminum coving can be designed to meet specific cleanroom standards and guidelines, such as ISO 14644, ensuring compliance with cleanliness requirements. It can be manufactured with smooth and rounded profiles that eliminate sharp corners or crevices, further reducing the potential for particle accumulation.

- Customization Options: Aluminum coving can be customized to fit the specific requirements of cleanroom panels. It can be fabricated in various sizes, profiles, and finishes to match the cleanroom design and desired aesthetic.

When incorporating aluminum coving into cleanroom panels, it’s important to consider factors such as cleanroom classification, material compatibility, and ease of cleaning. The coving should be installed in accordance with cleanroom construction practices and industry guidelines to maintain the integrity and cleanliness of the controlled environment.

It’s worth noting that cleanroom panels can be constructed using a variety of materials, including aluminum, stainless steel, and composite panels. The choice of panel material depends on the specific cleanroom requirements, such as desired cleanliness level, durability, and compatibility with other cleanroom components.

Be the first to review “Aluminium Coving R 50 With Backing” Cancel reply

Related products

Clean Room Panels & HVAC

Clean Room Panels & HVAC

Clean Room Panels & HVAC

Clean Room Panels & HVAC

Clean Room Panels & HVAC

Reviews

There are no reviews yet.